1.Weight measuring, bag making, filling, sealing, cutting and bags counting can be done automatically.

2.Computer PLC control and automatic alarming function.

3. English and Chinese human-machine operation interface, it is easy to operate, a high degree of automation.

4.High sensitivity photoelectric eye color tracing, more accuracy.

5. Famous brand components, ensure the quality and durability of the machine.

| Measurement Range | 1~100ml |

| Packing Size | L: 30-180mm W: 15-100mm |

| Packaging Speed | 30~80bags/min |

| Machine Size | (L)640*(W)700*(H)1580mm |

| Machine Weight | 300KG |

Sealing Style | Three/Four sealing /Back sealing |

| Cutting | Tooth Cut / Flat Cut |

| Power | 220V,50HZ,1.2KVA |

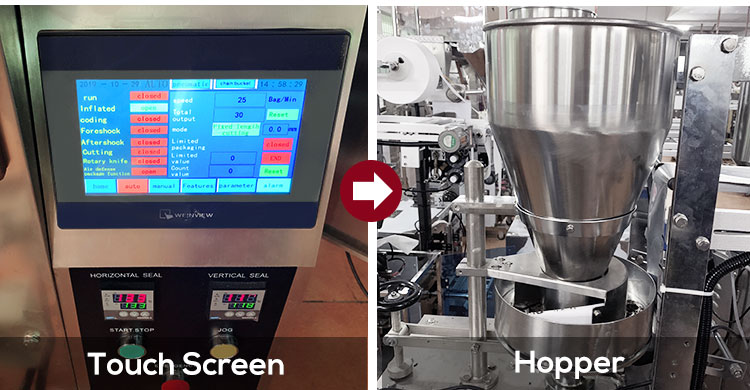

1st 1st step: Setting the parameters you want by touch screen

2nd step: Put the material into the stainless steel hopper

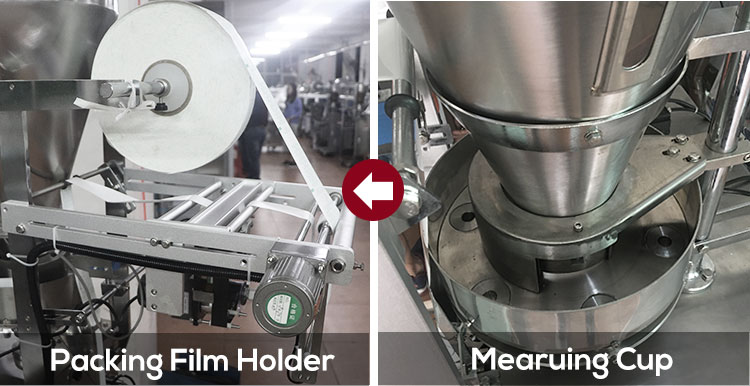

3rd step: The measurement parts will measure the weight of each bag automatically

4th step: The bag former will make the bag automatically

5th step: The horizontal and vertical cutter device will seal the middle and of the bag.

6th step: You will get the nicely paper or plastic bag type

Electrical configuration

These are the electrical configurations on the packaging machine, from different brands and different countries.

1.Weight measuring, bag making, filling, sealing, cutting and bags counting can be done automatically.

2.Computer PLC control and automatic alarming function.

3. English and Chinese human-machine operation interface, it is easy to operate, a high degree of automation.

4.High sensitivity photoelectric eye color tracing, more accuracy.

5. Famous brand components, ensure the quality and durability of the machine.