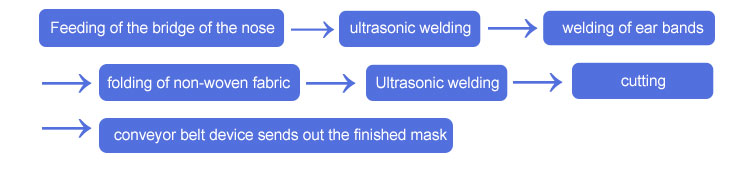

Brief Introduction of mask machine

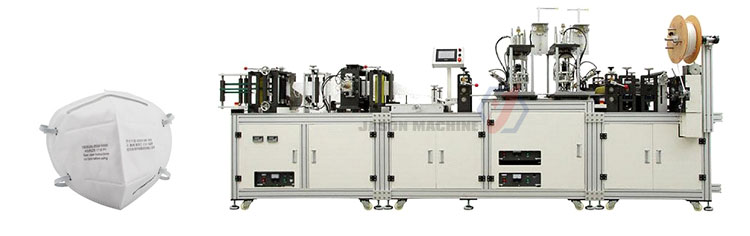

Fully automatic folding mask machine is a fully automatic machine for producing folding

mask production line. It uses ultrasonic technology to fuse 3 to 6 layers of PP non-woven

fabrics, activated carbon and filter materials, non-woven fabrics, ear bands, printing,

half-folding, edge-sealing, and roll cutting. It can also process 3M 9001, 9002 and other

folding masks. Depending on the raw materials used, the produced masks can reach

different standards such as FFP1, FFP2, N95, etc., without manual operation,

all are produced by mechanization.

Machine specification(3ply)

1.Unloading part of the machine: The unloading device of the machine adopts mechanical

tension control, which can keep consistent for any number of running of the machine,

including the acceleration, deceleration and uniform speed of the machine. Even in the

case of emergency shutdown, it can maintain consistency, ensuring that the material does

not shift, deform, wrinkle and other phenomena in the case of emergency shutdown.

2.Nasal bridge strip part: The nose bridge strip device uses a motor pulse transmission

system to achieve positioning, control speed, and position accuracy is very accurate.

3.Mould material: SKD11 is used for the grinding tool and cutter of this machine. It is a

general cold work die steel with high wear resistance and toughness. Abrasive steel is better.

In recent years, with the development of isotropic products, it has gradually developed

to high toughness. It can make the mold longer life, more stable performance,

hardness 58-60HRC.

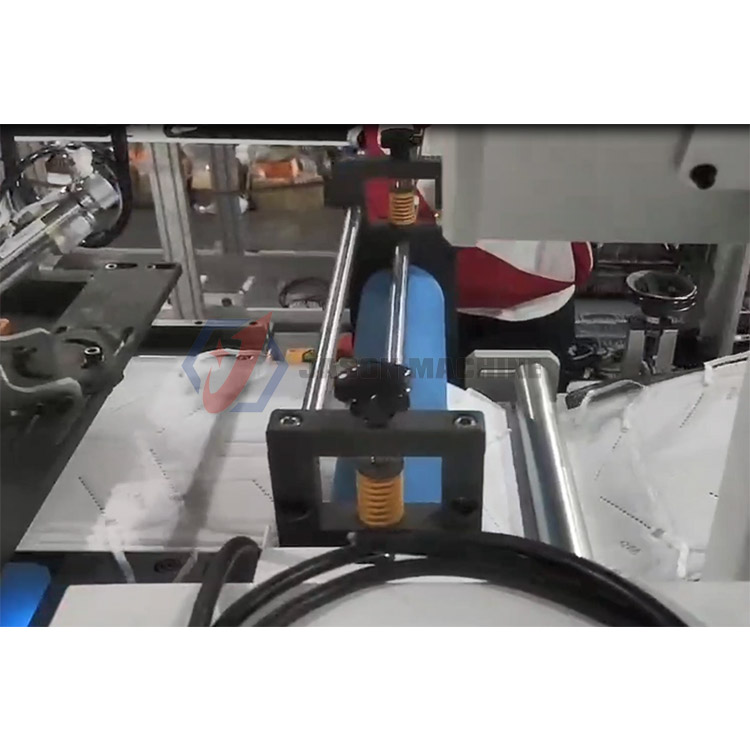

4.Ultrasonic: This machine uses high-power 15K ultrasonic, which has better welding effect

and stronger. The ultrasonic welding head uses SKD11 high wear-resistant abrasive tool

steel. The friction between the grinding tool and the surface of the ultrasonic welding

head (tens of thousands of high-frequency vibrations per second) forms a fusion between

molecular layers.

5.Accessories steel and aluminum concentrates: All parts of this machine are precision

machined by CNC, electroplated to improve wear resistance, heat resistance, electrical

conductivity, corrosion resistance and more durable.