1.Weight measuring, bag making, filling, sealing, cutting and bags counting can be done automatically.

2.Computer PLC control and automatic alarming function.

3. English and Chinese human-machine operation interface, it is easy to operate, a high degree of automation.

4.High sensitivity photoelectric eye color tracing, more accuracy.

5. Famous brand components, ensure the quality and durability of the machine.

| Measurement Range | 1~100ml |

| Packing Size | L: 30-180mm W: 15-100mm |

| Packaging Speed | 30~80bags/min |

| Machine Size | (L)640*(W)700*(H)1580mm |

| Machine Weight | 300KG |

Sealing Style | Three/Four sealing /Back sealing |

| Cutting | Tooth Cut / Flat Cut |

| Power | 220V,50HZ,1.2KVA |

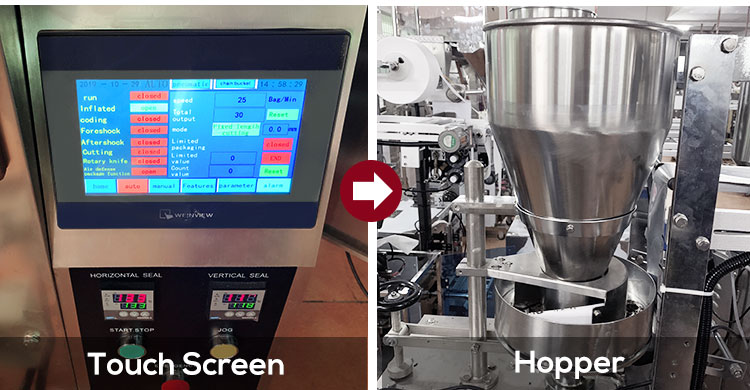

1st 1st step: Setting the parameters you want by touch screen

2nd step: Put the material into the stainless steel hopper

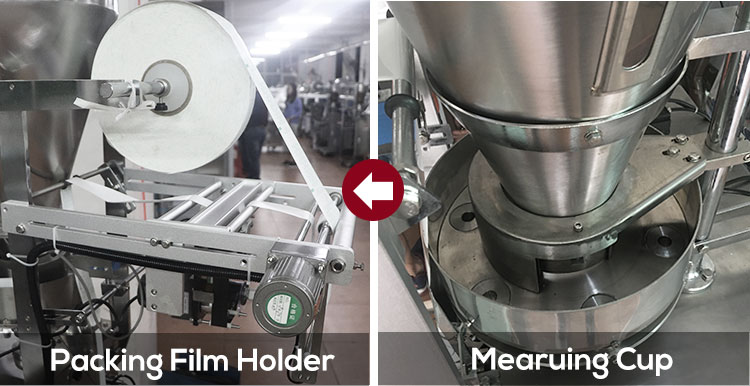

3rd step: The measurement parts will measure the weight of each bag automatically

4th step: The bag former will make the bag automatically

5th step: The horizontal and vertical cutter device will seal the middle and of the bag.

6th step: You will get the nicely paper or plastic bag type

Electrical configuration

These are the electrical configurations on the packaging machine, from different brands and different countries.